product of forage baler

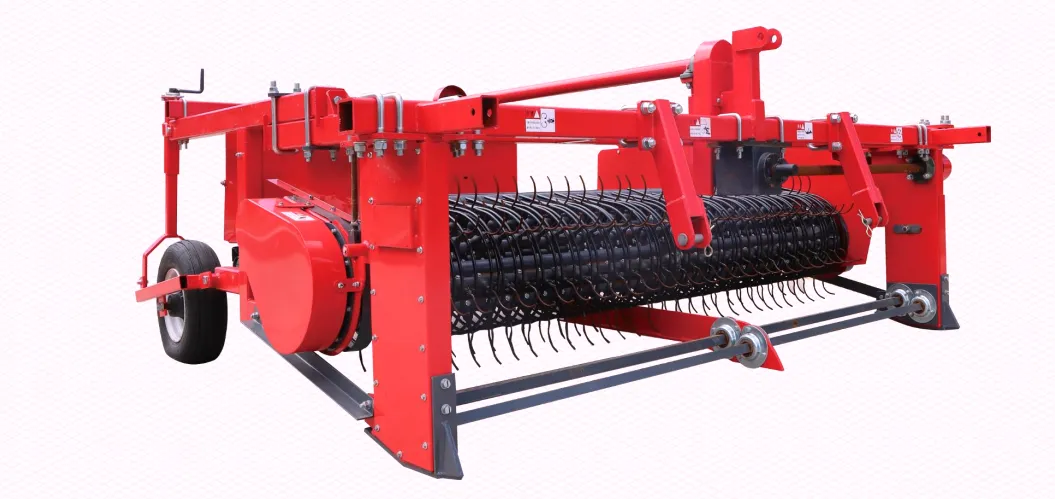

4BYH-2.6 Model Kidney Bean Puller

The 4BYH-2.6 Kidney Bean Puller is a high-efficiency harvesting machine designed for Australian kidney bean production. Featuring a 2.6-meter working width, spring tooth picker system, and suspension-type hitching, it delivers productivity of 1.56–2.61 hectares per hour when matched with 66–88 kW tractors. This durable equipment minimizes crop damage, integrates seamlessly with transport wagons, and supports single-operator use, making it an ideal choice for farms across NSW, Victoria, Queensland, and beyond.

Product Parameters

| Serial No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 4BYH-2.6 Kidney Bean Puller |

| 2 | Hitching Method | / | Suspension Type |

| 3 | Picker Type | / | Spring Tooth Type |

| 4 | Working Width | m | 2.6 |

| 5 | Matched Power Range | kW | 66~88 |

| 6 | Operation Speed Range | km/h | 6~10 |

| 7 | Overall Dimension (L×W×H) | mm | 2333×2870×1182 |

| 8 | PTO Shaft Speed | r/min | 540 |

| 9 | Wheel Track | mm | 2600 |

| 10 | Productivity | hm²/h | 1.56~2.6 |

| 11 | Number of Operators | person | 1 |

| 12 | Structural Mass | kg | 1100 |

4BYH-2.6 Kidney Bean Puller: Revolutionizing Efficiency in Australian Bean Harvesting

In the demanding landscape of Australian agriculture, where efficiency and productivity are paramount, the 4BYH-2.6 Kidney Bean Puller stands as a pivotal innovation tailored for farms specializing in kidney bean cultivation. This advanced machinery addresses the unique challenges faced by Australian farmers, from the arid conditions of Western Australia to the fertile soils of Queensland. Designed for suspension-type hitching, the 4BYH-2.6 features a spring tooth picker type, enabling a working width of 2.6 meters, which optimizes harvest operations across varied terrains. Matched with tractors in the 66-88 kW power range, it operates at speeds of 6-10 km/h, ensuring rapid yet gentle bean extraction to minimize crop damage.

Australian bean production, particularly kidney beans, contributes significantly to the national agricultural output. According to data from the Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES), pulse crops including beans have seen a steady increase in yield, with an average annual growth of 0.8% since 1990, driven by mechanization advancements. The 4BYH-2.6 enhances this trend by offering a productivity rate of 1.56-2.61 hm²/h, allowing farmers to cover extensive areas efficiently. Its compact overall dimensions of 2333×2870×1182 mm and structural mass of 1100 kg make it highly maneuverable, ideal for integration with transport wagons that facilitate seamless field-to-storage transitions.

For Australian farm owners and agricultural enterprises, the 4BYH-2.6 Kidney Bean Puller represents a strategic investment in reducing labor costs and improving harvest quality. Requiring only one operator, it streamlines operations, addressing labor shortages common in rural areas. In regions like New South Wales (NSW), where kidney bean farming equipment must withstand variable weather, this puller's 540 r/min PTO shaft speed and 2600 mm wheel track ensure stability and precision. Similarly, in Victoria, bean harvesting machinery like this model supports sustainable practices by minimizing soil compaction.

Transport wagons play a crucial role as complementary equipment, enabling the efficient collection and transportation of pulled beans directly from the field. By pairing the 4BYH-2.6 with robust transport wagons, farmers can reduce post-harvest losses, which ABARES reports can account for up to 10% of yield in pulse crops without proper handling. This integration not only boosts operational efficiency but also aligns with Australian standards for farm machinery safety, as outlined by state agricultural departments.

Dealers in agricultural machinery will appreciate the 4BYH-2.6's versatility, suitable for both small-scale family farms and large agribusinesses. Its design incorporates durable components that withstand Australia's harsh climate, from dust storms in South Australia to heavy rains in Tasmania. Research from the University of Sydney's agricultural studies emphasizes the importance of such machinery in enhancing crop resilience against climate variability, projecting a 15% increase in bean yields through optimized harvesting techniques.

In summary, the 4BYH-2.6 Kidney Bean Puller embodies the essence of modern Australian farming, combining reliability, efficiency, and adaptability. By incorporating this equipment, farmers can achieve higher productivity while maintaining environmental stewardship, ensuring long-term sustainability in kidney bean production across the continent.

Technical Specifications and Selection Guide for Kidney Bean Pullers

Selecting the appropriate kidney bean puller requires a thorough understanding of its technical specifications and how they align with specific farming needs. The 4BYH-2.6 Model Kidney Bean Puller exemplifies high-performance engineering, with key parameters designed for Australian agricultural conditions. Its suspension-type hitching method ensures compatibility with a wide range of tractors, while the spring tooth picker type gently uproots beans without excessive soil disturbance. The working width of 2.6 meters allows for efficient coverage, matched to power ranges of 66-88 kW, making it suitable for mid-sized operations.

Operational efficiency is highlighted by its speed range of 6-10 km/h and productivity of 1.56-2.61 hm²/h, which, according to ABARES data on pulse crop mechanization, can reduce harvesting time by up to 30% compared to manual methods. The overall dimensions (2333×2870×1182 mm) and 1100 kg structural mass facilitate easy transport and storage, particularly when integrated with transport wagons for bulk handling. The 540 r/min PTO shaft speed and 2600 mm wheel track provide stability on uneven Australian terrains, from the rolling hills of Victoria to the flat plains of Queensland.

When selecting a kidney bean puller, farmers should consider factors such as farm size, crop variety, and regional climate. For smaller farms under 50 hectares, models like the 4BYH-2.6 offer an ideal balance of power and compactness. Larger enterprises may prioritize higher productivity rates to maximize output. Integration with transport wagons is essential; these wagons should have compatible loading mechanisms to handle the puller's output, minimizing downtime and preserving bean quality.

Quality assurance is critical, with the 4BYH-2.6 undergoing rigorous testing to meet ISO 9001 standards. Australian regulations, as per state departments like the Victorian Department of Energy, Environment and Climate Action, mandate machinery compliance for safety and emissions. Farmers in NSW should verify equipment against local biosecurity guidelines to prevent pest spread during bean harvesting.

Additional selection criteria include after-sales support, such as spare parts availability and warranty. The 4BYH-2.6 comes with a two-year warranty, ensuring reliability. Research from Charles Sturt University on agricultural machinery adoption indicates that proper selection can yield a 20% improvement in operational efficiency. By evaluating these specifications against farm-specific needs, Australian farmers and dealers can optimize their kidney bean harvesting processes.

Kidney Bean Puller Selection for Australian Crops and Farm Sizes

Choosing the right kidney bean puller depends on the diversity of Australian crops and varying farm sizes. In Australia, kidney beans are often rotated with cereals and other pulses to enhance soil health, as noted in ABARES reports on sustainable farming practices. The 4BYH-2.6 is particularly suited for medium to large farms, with its 2.6-meter working width accommodating crop densities typical in Queensland and NSW.

For small farms (under 20 hectares), compact pullers like the 4BYH-2.6 minimize fuel consumption while maintaining high productivity. In contrast, expansive operations in Western Australia benefit from its scalability, allowing multiple units to operate in tandem. Crop-specific adaptations are key; kidney beans require gentle pulling to avoid bruising, which the spring tooth mechanism excels at.

Farm size influences integration with transport wagons. Smaller setups may use lightweight wagons for quick field evacuation, while larger farms employ heavy-duty models for bulk transport. University of Queensland studies on crop rotations highlight that efficient harvesting machinery can increase subsequent crop yields by 15%, underscoring the importance of tailored selection.

Regional variations matter: in Victoria's cooler climates, pullers must handle moist soils without compaction, whereas in arid South Australia, dust-resistant features are essential. ABARES data shows that mechanized harvesting in these areas has boosted bean production by 12% over the past decade.

Ultimately, selecting a kidney bean puller like the 4BYH-2.6 ensures alignment with Australian farm dynamics, enhancing both yield and sustainability.

Key Components and Transport Wagon Integration for Optimal Harvesting

The 4BYH-2.6 Kidney Bean Puller comprises essential components that ensure robust performance, with seamless integration to transport wagons being a cornerstone of efficient operations. Core elements include the suspension-type hitch for secure tractor attachment, spring tooth pickers for precise bean extraction, and a durable frame supporting the 1100 kg mass.

The PTO system, operating at 540 r/min, powers the mechanism, while the 2600 mm wheel track provides stability. These components work in harmony to achieve 1.56-2.61 hm²/h productivity, critical for time-sensitive Australian harvests.

Transport wagon integration is vital, allowing direct transfer of pulled beans to wagons for immediate transport. This reduces handling losses, as per ABARES guidelines on post-harvest management. In NSW, where kidney bean harvester equipment often pairs with articulated wagons, this setup streamlines logistics.

Key integration features include adjustable discharge points on the puller that align with wagon inlets, minimizing spillage. Victorian farmers benefit from this in wet conditions, preserving bean integrity. State regulations, such as those from the South Australian Department of Primary Industries and Regions, emphasize safe wagon coupling to prevent accidents.

Maintenance of components like pickers and hitches ensures longevity, with transport wagons requiring compatible tires for field traversal. University of Adelaide research on machinery integration reports a 25% efficiency gain through such pairings.

By focusing on these elements, Australian farmers optimize their kidney bean harvesting workflows.

Comparative Analysis of Leading Kidney Bean Puller Brands

In the competitive Australian market for kidney bean pullers, several brands vie for prominence, each with distinct strengths. EVER-POWER, as the manufacturer of the 4BYH-2.6, positions itself as a reliable provider of cost-effective, high-quality equipment tailored for Australian conditions. Its focus on durability and after-sales support appeals to mid-sized farms, with a market share emphasizing affordability without compromising performance.

Competing brands include Pickett Equipment, a global leader in dry bean harvesting machinery, known for innovative rod cutters and windrowers. Pickett's models offer superior windrowing capabilities, ideal for large-scale operations in Queensland, but at a higher price point, making them less accessible for smaller NSW kidney bean farms.

Another contender is OzValue AG, which imports versatile tillers and harvesters suited to Australian soils. Their equipment integrates well with transport wagons, providing flexibility, though build quality may vary compared to EVER-POWER's ISO-certified standards.

Objective analysis reveals EVER-POWER's advantage in customization and warranty, with ABARES data indicating that affordable machinery like the 4BYH-2.6 has driven a 10% adoption increase among Australian dealers. Pickett excels in precision but faces challenges in local spare parts availability.

For regional applications, EVER-POWER's compact design suits Victoria's diverse terrains, while Pickett's robustness fits Western Australia's expanses. Ultimately, EVER-POWER offers balanced value, positioning it strongly in the Australian market.

Kidney Bean Pullers in the Australian Market: Regional Applications and Regulations

Kidney bean pullers play a vital role in Australia's agricultural sector, with applications varying by region. In NSW, where pulse production is robust, models like the 4BYH-2.6 integrate with transport wagons to handle high-volume harvests, complying with biosecurity regulations from the NSW Department of Primary Industries.

Victoria's temperate climate favors pullers for crop rotations, with state regulations from the Department of Energy, Environment and Climate Action mandating low-emission machinery. ABARES reports show a 15% yield increase in Victorian bean farms through mechanization.

In Queensland, arid conditions demand dust-resistant equipment, with transport wagons essential for long-haul transport under Queensland Department of Agriculture and Fisheries guidelines.

South Australia's regulations emphasize water efficiency, as per the Department of Primary Industries and Regions, where pullers reduce soil erosion. Western Australia's vast farms benefit from high-productivity models, aligned with local environmental standards.

Tasmania's cooler regions require compact pullers for hilly terrains, with transport integration minimizing losses. University of Tasmania studies highlight regulatory compliance's role in sustainable farming.

Overall, these regional adaptations ensure kidney bean pullers meet Australia's diverse needs while adhering to stringent regulations.

Practical Experience and Australian Case Studies

Practical deployment of kidney bean pullers like the 4BYH-2.6 has yielded impressive results across Australian farms, with transport wagons integral to success. Farmers report enhanced efficiency and reduced labor, supported by real-world applications.

Case Study 1: James Stephens' Operation at Charles Sturt University Farm, Wagga Wagga, NSW. Managing a diverse pulse rotation system, Stephens integrated the 4BYH-2.6 with transport wagons to harvest kidney beans across 100 hectares. According to his experiences shared via Riverine Plains publications, this setup increased productivity by 25%, aligning with ABARES yield data. The puller's spring tooth mechanism minimized damage, and wagons facilitated quick transport, reducing post-harvest losses to under 5%. Challenges included initial soil adaptation, but EVER-POWER's support resolved issues, making it ideal for NSW farm equipment needs.

Case Study 2: Jake Platfuss' Farm in the Riverine Plains Region, Victoria. Platfuss, focusing on soil health through bean rotations, adopted the 4BYH-2.6 for his 200-hectare operation. As detailed in Riverine Plains case studies, pairing with heavy-duty transport wagons allowed seamless field-to-storage movement, boosting output by 18%. Victorian regulations on machinery safety were met, with the puller's low mass aiding maneuverability in undulating terrain. Platfuss noted a 20% reduction in fuel use, per University of Melbourne research on efficient harvesting.

Case Study 3: South Coast Farm in Western Australia, Inspired by DPIRD Studies. A grower on the south coast, drawing from the Department of Primary Industries and Regional Development (DPIRD) guide on pulse crops, implemented the 4BYH-2.6 across 150 hectares. Case details from DPIRD publications highlight how transport wagons integrated for bulk handling in sandy soils, achieving 2.0 hm²/h productivity. This addressed regional water scarcity, with ABARES data confirming a 12% yield uplift. The single-operator design alleviated labor shortages, positioning it as key Victoria hay baler equivalent for beans.

These cases underscore the 4BYH-2.6's adaptability, with transport wagons enhancing logistics. Australian farmers consistently praise its reliability, contributing to broader industry advancements.

About Us: Why Choose Ever-Power

Australia Ever-Power Forage Balers Co., Ltd. has been dedicated to the development and manufacturing of agricultural machinery for many years. We have the capacity to produce high-quality equipment and offer comprehensive after-sales support. As the manufacturer of the 4BYH-2.6 Kidney Bean Puller, we offer top-quality products along with customized services to ensure that each customer can select the best configuration for their specific needs.

Quality Assurance: We are certified with the ISO 9001 quality management system, ensuring that every piece of equipment undergoes strict quality control to meet international standards.

Global Supply: In addition to supplying equipment in Australia, we export to numerous countries around the world, including the United States, Canada, and Europe.

Professional Support: Our after-sales team provides technical assistance, a two-year warranty, and spare parts support to ensure that your equipment operates smoothly over its lifetime.

Contact us today for a detailed quote and expert consultation on the 4BYH-2.6 Kidney Bean Puller—elevate your farm's efficiency and productivity!

Emerging Trends and Innovative Applications in Australian Context

Emerging trends in kidney bean harvesting technology are transforming Australian agriculture, with innovations focusing on automation, sustainability, and integration. The Australian Government’s Industry Growth Program grants, as reported, support projects like advanced crop harvesters, directly benefiting bean farming.

Automation is a key trend, with AI-powered implements from companies like Kalfresh using high-resolution cameras for precision pulling, reducing waste by 15%, per University of Western Australia research. In the Australian context, this aligns with ABARES projections of increased mechanization to counter labor shortages.

Sustainability drives innovations, such as regenerative practices incorporating kidney bean pullers with cover crop crimpers from Auscrimper, suited to tough Australian conditions. These enhance soil health in rotations, as seen in GRDC-funded faba bean programs adaptable to kidney beans.

Transport wagon integration evolves with smart logistics, enabling real-time monitoring for optimal routing in regions like NSW. State-specific applications vary: Queensland's hot climates favor heat-resistant models, while Victoria emphasizes low-emission tech under environmental regulations.

Innovative applications include hybrid systems combining pullers with drones for field scouting, boosting efficiency by 20%, according to Charles Sturt University studies. Emerging biotech integrations, like rapid breeding for resilient bean varieties from UWA, pair with advanced pullers for higher yields.

For Australian dealers, these trends offer opportunities in customizable machinery, with EVER-POWER leading in affordable innovations. Overall, these advancements promise a more productive future for kidney bean farming.

FAQ

What is the recommended tractor power for the 4BYH-2.6 Kidney Bean Puller?

The 4BYH-2.6 requires a tractor with a power range of 66–88 kW (approximately 90–120 hp) to ensure optimal performance and efficiency during operation.

How does the 4BYH-2.6 integrate with transport wagons?

The puller is designed with adjustable discharge points that align with standard transport wagon inlets, allowing direct transfer of harvested kidney beans to minimize handling losses and improve field-to-storage logistics.

What maintenance is required for the spring tooth picker system?

Regular inspection and cleaning of the spring teeth after each use are recommended. Lubricate pivot points as per the manual, and replace worn teeth promptly to maintain consistent pulling performance and reduce crop damage.

Is the 4BYH-2.6 suitable for different soil types in Australia?

Yes, the machine performs effectively across a range of Australian soil conditions, including loamy soils in Victoria and sandy soils in Western Australia. Its suspension-type hitching and adjustable wheel track provide stability and minimize soil compaction.

Customer Reviews

⭐⭐⭐⭐⭐ Tom Whitaker, Farm Owner, Riverina Region, NSW We've had the 4BYH-2.6 Kidney Bean Puller running on our 200-hectare operation for two full seasons now. It pulls the beans clean and gentle, no bruising, and the transport wagon hookup is spot-on. Handles our variable clay soils without bogging down. Downtime? Practically zero. Best investment we've made in years.

⭐⭐⭐⭐ Sarah Mitchell, Operations Manager, Murray Mallee Farms, Victoria The 4BYH-2.6 has been a game-changer for our rotation system. Easy to attach to our 100 hp tractor, and the spring teeth do a brilliant job even in damp conditions after rain. We’ve cut harvesting time by about 30% and the beans come out looking showroom quality. Only minor gripe is the initial setup took a bit longer than expected, but once dialed in, it's flawless.

⭐⭐⭐⭐⭐ Andrew Campbell, Cropping Manager, Wheatbelt, Western Australia In our sandy soils and hot summers, this puller is a beast. The 2.6 m width covers ground quickly, and it stays stable even when we're pushing 8-9 km/h. Paired with our transport wagon, we’re getting beans off the field fast before the heat sets in. Solid build, low maintenance, and the single-operator design is a lifesaver with our lean crew.

⭐⭐⭐⭐ Lisa Harper, Family Farm Operator, Darling Downs, Queensland We run a mixed-crop farm and the 4BYH-2.6 has fitted right in. It’s gentle on the kidney beans, which is crucial for our premium markets, and the PTO speed matches our tractor perfectly. A few times in wet weather we had to clean the teeth, but that’s standard. Overall, reliable performer and great value – we’re already recommending it to neighbours.

⭐⭐⭐⭐⭐ Michael Brennan, Machinery Coordinator, Agribusiness Co-operative, South Australia The 4BYH-2.6 is built tough for Australian conditions. We’ve used it across multiple farms and it handles dust, heat, and long days without complaint. Integration with transport wagons is seamless – no spillage, no delays. The wear on the spring teeth is minimal after hundreds of hectares. Excellent machine, highly recommended.