Forage Balers

We offer both round and square forage balers designed for hay, silage, and crop residues. They help farmers efficiently bale harvested materials, making transport and storage easier.

What are forage balers?

Forage balers for Sale

We are a professional manufacturer of heavy-duty silage balers with over 20 years of experience. Below are our most popular models for the Australian market. If you cannot find the product you need, please feel free to email us; we accept customizations – and usually reply within hours.

Showing 1–8 of 24 results

-

4BYH-1.3 Kidney Bean Puller

-

4BYH-2.6 Model Kidney Bean Puller

-

4BYH-3.25 Kidney Bean Puller(4 Ridges Pushing Type)

-

4BYH-3.25 Kidney Bean Puller(5 Ridges)

-

4BYHD/4BYHS-3.9 Kidney Bean Puller (6 Ridges)

-

9F-70 Animal Feed Grass Grinder Machine

-

9GD-2.5 Model Traction Single-Blade Mower

-

9GD-2.5 Traction Single-Blade Mower

How Forage Balers Work

Core Advantages of Our Forage Balers

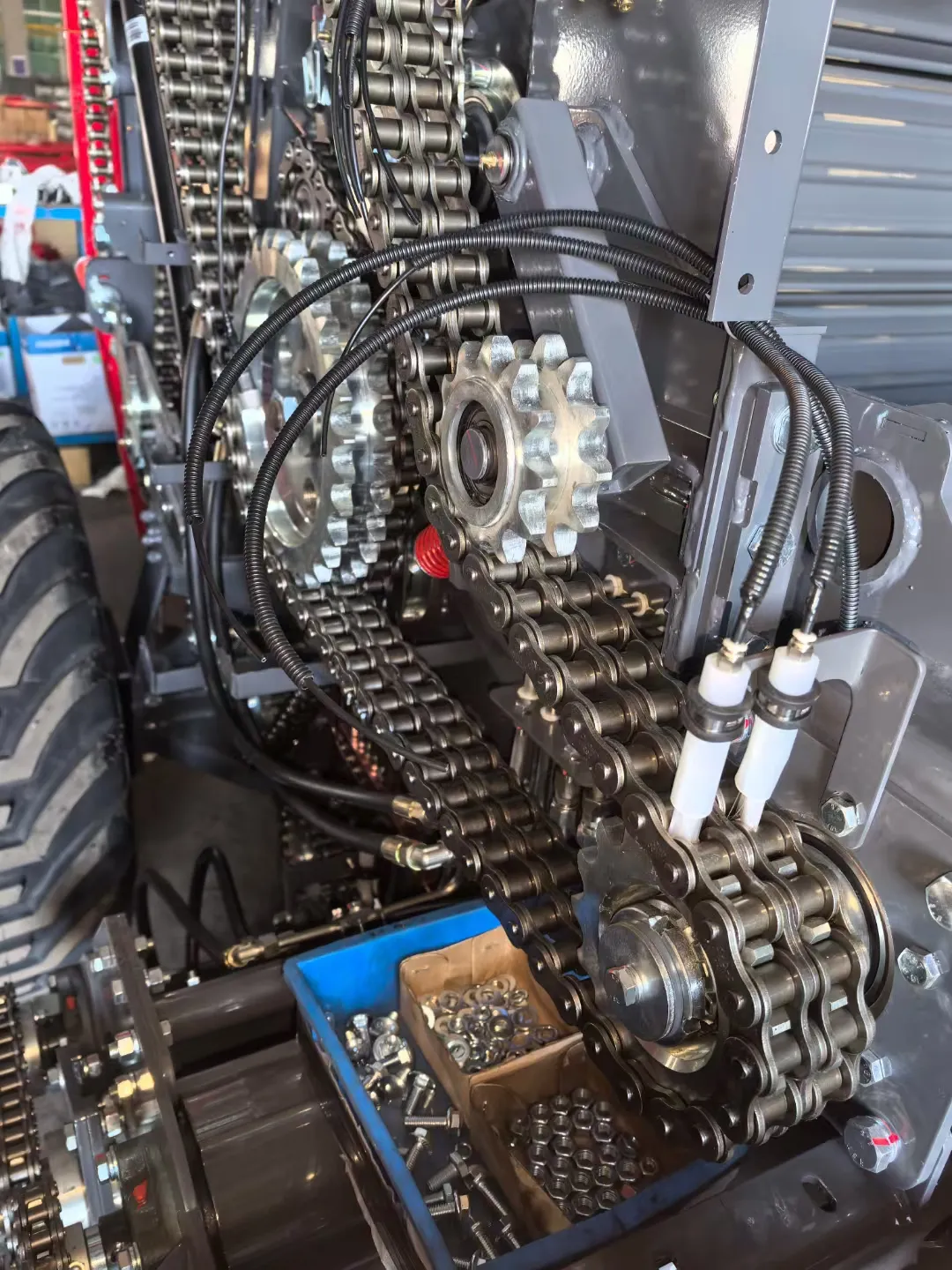

1. Stable Structure and Reliable Durability

The balers use reinforced frames, heavy-duty chain drives, and rigid towing components. This design helps the machine maintain stability during long hours of high-density baling. The adjustable hitch allows the baler to adapt to small fields and uneven ground, reducing driveline stress when making tight turns.

2. Smooth Pickup and Consistent Feeding

Most models are equipped with a cam-less pickup and a semi-forced feeding system, allowing material to enter the chamber more evenly and reducing blockages. On certain models, the pickup can switch between tine and hammer-type assemblies, making it suitable for forage, straw, and even standing corn stalks.

3. Adjustable Density for Different Crop Conditions

Bale density is automatically controlled by sensors, with most models operating within the 100–200 kg/m³ range. Operators can adjust settings based on moisture levels—tight for silage, moderate for hay, and flexible for straw—so that bales remain stable during handling, transport, and storage.

4. Mature and Reliable Net-Wrapping System

All models feature automatic net wrapping. Standard net widths (1.25 m or 1.4 m) are widely available and easy to source. The simple tensioning system helps maintain even coverage and reduces issues such as loose wrapping or bale slippage.

5. Steady Operating Efficiency

Depending on field conditions and material volume, production rates typically reach 40–100 bales per hour, with operating speeds of 5–35 km/h. The common pickup width of around 2.24 m provides good coverage in large fields and improves overall workflow.

6. Easy Maintenance and Unified Spare Parts

Many components—chains, pickup tines, rollers—share standardized specifications across different models, making parts storage and replacement straightforward. The machine layout is clear and accessible, allowing routine maintenance to be completed quickly.

7. Clear Support and Service Options

Standard warranty coverage is provided, along with remote technical assistance. Most common issues can be resolved through video guidance, minimizing downtime. The company has years of export experience, including service support in Mongolia and Russia.

Applications of Forage Balers

Silage Baling

When crops like corn stalks or alfalfa still hold a high moisture content, farmers use a silage baler to form the bales before wrapping them in plastic film. This creates sealed silage that ferments properly and retains nutrients, making it a high-quality feed for dairy cows and sheep.

Dry Hay Storage

After forage is sun-dried, a hay baler is used to form dense bales—typically around 140 kg/m³. These bales stack well in storage without collapsing, stay cleaner, and resist moisture far better than loose hay.

Straw Collection and Reuse

Once wheat or rice is harvested, the remaining straw in the field can be baled directly. The bales are then hauled off as roughage for cattle and sheep, or sold to biomass power plants as a renewable fuel source.

Custom Baling Services

Many operators run a round baler as a mobile service, traveling from farm to farm during the busy season. They bale alfalfa or hay for neighboring growers and typically earn by volume—often handling work for three or four farms in a single day.

Maintenance and Care for Forage Balers

Daily Routine (about 10 minutes after work)

-

Clear debris from the pickup, feeding area, and front of the chamber.

-

Check chains and pickup tines for wrapped material or foreign objects.

-

Apply grease to the main lubrication points.

-

Inspect chain tension and adjust when needed.

Weekly Check (around 30 minutes)

-

Inspect gearbox oil level and top up with 80W-90 gear oil if necessary.

-

Check belts and chains for wear, cracks, or looseness.

-

Examine the net-wrap tensioning and brake components.

-

Inspect hydraulic fittings for leaks.

Seasonal or Long-Term Storage

-

Replace gearbox oil according to the recommended interval (typically around 500 hours).

-

Apply rust-prevention spray to chains, rollers, and the wrapping mechanism.

-

Check wear parts such as tines, hammers, and bearings, and replace when needed.

-

Store the machine indoors and cover it to avoid sun and moisture exposure.

How to Choose the Right Forage Baler

Selecting a suitable baler comes down to four key factors: tractor horsepower, annual bale volume, crop moisture, and field size. The following recommendations are aligned with the real parameters of the 9YG-1.0C, 9YG-2.24D, 9YG-1.25, and the 9YCM-850 baler-wrapper models shown in the product document.

Case Studies

Australia Ever-power Forage Balers Co., Ltd. is a leading professional manufacturer of agricultural machinery with nearly 100 patented technologies covering core innovations in round balers and hay rakes. All product development is conducted using advanced computer-aided design (CAD) systems to ensure precision and reliability. Our in-house testing laboratory operates in full compliance with international standards, including ISO 4254-11:2010 (Agricultural machinery safety – Pick-up balers) and ISO 4254-14:2016 (Agricultural machinery safety – Bale wrappers). Every machine carries CE certification and is produced under an ISO 9001:2015-certified quality management system, meeting the safety and performance requirements of the European Union and other major global markets.

We operate two dedicated, modern production lines for round balers and hay rakes, each with an annual capacity of 2,000 units. The factory is equipped with nearly 100 sets of advanced machinery, including CNC laser cutting centers, automated welding lines, and electrostatic powder-coating systems. These facilities deliver exceptional manufacturing accuracy, durability, and finish consistency.

Our products are exported to Mongolia and Russia.

Our products are exported to Kazakhstan.

The company actively exhibits at major international events such as the China-Russia Expo and the China-Mongolia Expo, where we have secured significant orders and built long-term partnerships, particularly in the Russian and Mongolian markets. Recognized as a National High-Tech Enterprise in Australia and recipient of multiple provincial awards for engineering excellence, we continue to strengthen our reputation in the global forage baler industry.

With products now exported to more than 40 countries and regions, Australia Ever-power Forage Balers Co., Ltd. remains committed to providing reliable, high-performance forage harvesting and baling solutions that help farmers around the world improve efficiency and feed quality.

Frequently Asked Questions

Which countries can you ship forage balers to? Who covers shipping and customs duties?

Last year we shipped to over 40 countries including the United States, Canada, Australia, New Zealand, Germany, France, Poland, Brazil, Argentina, South Africa, and many more. All machines are shipped by 20ft/40ft sea containers. We offer both FOB and CIF terms. Ocean freight is paid to the destination port, and import duties, taxes, and customs clearance are handled by the buyer. We provide full sets of commercial invoices, packing lists, certificates of origin, and fumigation certificates.

How long does it take from order to delivery of the forage balers?

Standard models in stock: 7-15 days from factory. Custom paint or machines with net-wrap system added: 25-35 days. Sea shipping time:

- West Coast USA: 40-50 days

- East Coast USA: 55-65 days

- Europe: 30-45 days

- Australia/New Zealand: 35-45 days Urgent orders can go by air freight, but the cost is considerably higher

Are spare parts easy to get? If something breaks in the US or Australia, can I source parts locally?

About 80% of the chains, bearings, twine knotters, and belts are fully compatible with John Deere, New Holland, and Krone, so most local farm equipment dealers already stock them. We also keep over RMB 10 million worth of spare parts in stock year-round. If anything goes wrong, just send photos via WhatsApp – we’ll identify the part and ship it via DHL within 24 hours (free of charge during warranty). Most parts arrive on your farm in 4-7 days.

Our Certificates