Prasy do kiszonki to kluczowe maszyny do konserwacji roślin pastewnych, takich jak trawa, kukurydza czy lucerna, w stanie świeżym i wilgotnym, stanowiącym paszę dla zwierząt. W przeciwieństwie do siana, które jest suszone przed belowaniem, kiszonka jest fermentowana i przechowywana w środowisku beztlenowym, aby zachować jej wartości odżywcze. Prasy do kiszonki pomagają rolnikom efektywnie zbierać, prasować i przechowywać te rośliny, zapewniając ich odpowiednią konserwację do całorocznego użytkowania. W tym artykule omówimy, czym jest prasa do kiszonki, jak działa, jakie są jej rodzaje i dlaczego jest niezbędna w gospodarstwach hodowlanych.

Wstęp

Dla hodowców zwierząt gospodarskich utrzymanie stałego dopływu wysokiej jakości paszy ma kluczowe znaczenie dla zdrowia i wydajności zwierząt. Jednym ze sposobów osiągnięcia tego celu jest zbieranie plonów w stanie świeżym i wilgotnym oraz przetwarzanie ich na kiszonkę. Kiszonka to sfermentowana pasza, która jest konserwowana w procesie fermentacji beztlenowej. W przeciwieństwie do suchego siana, które może tracić składniki odżywcze podczas suszenia, kiszonka zachowuje więcej wartości odżywczych.

Prasy do kiszonki to specjalistyczne maszyny, które pomagają zbierać, prasować i owijać kiszonkę, tworząc zwarte, szczelne bele, które można przechowywać do późniejszego wykorzystania. Maszyny te są przeznaczone do pracy z paszą o wysokiej wilgotności i wyposażone w specjalne funkcje zapewniające prawidłową fermentację i konserwację. W tym artykule zagłębimy się w mechanikę pras do kiszonki i ich rolę w działalności rolniczej.

Czym jest prasa do kiszonki?

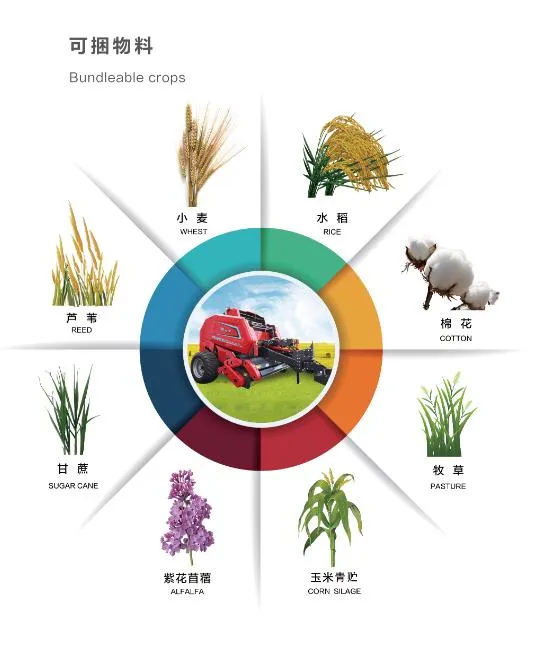

A prasa do kiszonki to maszyna przeznaczona do zbioru, prasowania i owijania roślin pastewnych wykorzystywanych do produkcji kiszonki. Kiszonka jest zazwyczaj zbierana z roślin takich jak kukurydza, trawa lub lucerna, ścinanych w stanie świeżym i wilgotnym. Celem jest zachowanie składników odżywczych w plonie poprzez fermentację w szczelnym środowisku, co ułatwiają prasy do kiszonki.

Główne cechy pras do kiszonki:

-

Zarządzanie wilgociąPrasy do kiszonki są przystosowane do pracy z mokrą paszą, zazwyczaj o poziomie wilgotności od 50% do 70%. W przeciwieństwie do pras do siana, które obsługują suchszy materiał.

-

Kompresja i uszczelnianie:Prasy do kiszonki ściśle prasują paszę w bele, a następnie owijają je siatką lub folią, tworząc hermetyczne zamknięcie, które zapobiega przedostawaniu się tlenu.

-

Kontrola fermentacjiProces fermentacji ma kluczowe znaczenie w produkcji kiszonki. Poprzez szczelne zgrzewanie bel, prasa pomaga stworzyć beztlenowe środowisko niezbędne do fermentacji, zachowując wartości odżywcze plonu.

Jak działa prasa do kiszonki?

Proces belowania kiszonki obejmuje kilka etapów, z których każdy jest kluczowy dla zachowania plonu. Oto opis krok po kroku działania typowej prasy do kiszonki:

Zbiór plonów

Proces rozpoczyna się od zbioru roślin pastewnych. Rolnicy używają sieczkarnia paszowa lub kosiarki do ścinania plonu, gdy jest on w optymalnej fazie produkcji kiszonki. Zazwyczaj ma to miejsce, gdy plon jest w fazie zwartej, z wystarczającą wilgotnością, ale nie na tyle mokro, aby spowodować psucie się.

Odbiór plonów

Po skoszeniu paszy, grabie lub zgrabiarka zbierają ją w pokosy, ułatwiając prasie zbieranie plonu. Prasy do kiszonki są wyposażone w szerokie mechanizmy podbierające, które umożliwiają efektywne zbieranie i transportowanie materiału do komory prasowania.

Belowanie

Gdy pasza trafia do prasy, jest mocno sprasowana. Prasy do kiszonki posiadają specjalnie zaprojektowane mechanizmy, takie jak: podajniki bębnowe obrotowe Lub systemy rolkowe, do obsługi mokrej i ciężkiej paszy. Te elementy zapewniają ścisłe upakowanie kiszonki w belę, tworząc bele o wysokiej gęstości.

Zawijanie

Jednym z kluczowych etapów procesu belowania kiszonki jest owijanie. Po sprasowaniu paszy prasa automatycznie owija belę warstwą folii lub siatki. Owijanie to zapewnia szczelność beli i zapobiega dostępowi tlenu do kiszonki, co jest niezbędne do procesu fermentacji. Niektóre nowoczesne prasy do kiszonki wyposażone są w automatyczne systemy owijania, które przyspieszają i usprawniają proces.

Składowanie

Po owinięciu i uszczelnieniu beli można ją przechowywać na polu lub w stodole. Ważne jest, aby bele były przechowywane w miejscu chronionym przed bezpośrednim działaniem promieni słonecznych, ponieważ może to spowodować degradację folii i zwiększyć ryzyko wystąpienia pleśni. Bele kiszonki można również przechowywać w stosach, aby efektywnie wykorzystać przestrzeń.

Fermentacja

Kiszonka zaczyna fermentować w zamkniętych belach, a proces ten trwa zazwyczaj kilka tygodni. Idealne środowisko fermentacji to środowisko beztlenowe (beztlenowe), dlatego owijanie jest tak istotne. Z czasem cukry zawarte w paszy są przekształcane przez bakterie w kwas mlekowy, który obniża pH i zapobiega psuciu się paszy, skutecznie konserwując ją przez miesiące.

Dlaczego prasa do kiszonki jest ważna dla gospodarstw rolnych?

Dla wielu hodowców zwierząt gospodarskich kiszonka jest kluczowym elementem strategii żywieniowej, szczególnie w miesiącach zimowych lub w porze suchej, gdy brakuje świeżej paszy. Wydajność pras do kiszonki ma bezpośredni wpływ na produktywność i wyniki finansowe gospodarstwa. Oto kilka powodów, dla których prasy do kiszonki są ważne:

Konserwacja składników odżywczych

Kiszonka pozwala rolnikom zachować wartości odżywcze swoich upraw. Proces fermentacji pomaga utrzymać poziom energii i białka w uprawie, zapewniając zdrową i zbilansowaną dietę dla zwierząt gospodarskich.

Zmniejszona ilość odpadów

W przypadku belowania plonów na kiszonkę ryzyko strat jest mniejsze w porównaniu z tradycyjnym sianem, które może tracić składniki odżywcze podczas suszenia. Dzięki zachowaniu wilgoci w paszy, kiszonka zachowuje więcej składników odżywczych.

Wygoda i wydajność

Prasy do kiszonki znacznie przyspieszają proces zbioru, prasowania i magazynowania paszy. Dzięki funkcjom automatyzacji maszyny te mogą szybko owijać i zgrzewać bele, zmniejszając ilość pracy ręcznej. Dodatkowo, bele kiszonki są łatwe w przechowywaniu i transporcie, co jest szczególnie przydatne w dużych gospodarstwach rolnych.

Całoroczne dostawy pasz

Możliwość przechowywania kiszonki w szczelnie zamkniętych belach oznacza, że rolnicy mają dostęp do wysokiej jakości paszy przez cały rok, nawet gdy nie ma dostępu do świeżego pastwiska. Jest to szczególnie korzystne w regionach o długich zimach lub suszy.

Rodzaje pras do kiszonki

Na rynku dostępnych jest kilka rodzajów pras do kiszonki, z których każda została zaprojektowana z myślą o konkretnych potrzebach. Do najpopularniejszych typów należą:

Prasy do kiszonki okrągłej

Prasy do kiszonki okrągłej to najpopularniejszy typ pras do kiszonki. Maszyny te wytwarzają duże, cylindryczne bele, które są łatwiejsze w obsłudze, przechowywaniu i transporcie. Idealnie nadają się do dużych gospodarstw i są powszechnie używane do belowania kiszonki z trawy lub kukurydzy.

Prasy do kiszonki w kostce

Prasy do kiszonki w kształcie kwadratu produkują bele prostokątne, które można sprawniej układać w stosy i które zapewniają bardziej kompaktowe wymiary podczas przechowywania. Są one zazwyczaj używane w mniejszych gospodarstwach, gdzie bele muszą być obsługiwane ręcznie lub przechowywane w pomieszczeniach.

Prasy stałokomorowe

Prasy stałokomorowe to prostsze maszyny, które formują bele o jednakowym rozmiarze. Prasy te są wydajne i proste w obsłudze, co czyni je dobrym wyborem dla rolników poszukujących niezawodnej i łatwej w utrzymaniu maszyny do belowania kiszonki.

Prasy o zmiennej komorze

Prasy zmiennokomorowe umożliwiają regulację rozmiaru beli w zależności od ilości prasowanej paszy. Prasy te oferują większą elastyczność, umożliwiając rolnikom dostosowanie rozmiaru beli do warunków uprawy i potrzeb magazynowych.

Kluczowe cechy, na które należy zwrócić uwagę przy wyborze prasy do kiszonki

Przy wyborze prasy do kiszonki należy wziąć pod uwagę kilka cech, które mogą pomóc zwiększyć wydajność i zachować jakość kiszonki:

Automatyczne systemy owijania

Prasy do kiszonki z automatycznym systemem owijania oszczędzają czas i pracę, automatycznie owijając belę po jej sprasowaniu. Systemy te zazwyczaj wykorzystują folię plastikową, która szczelnie zamyka belę.

Systemy wysokiego sprężania

Poszukaj prasy do kiszonki z systemem wysokiego zgniotu, która pozwoli Ci formować gęste bele. Im gęstsza bela, tym lepiej zachowa swój kształt podczas przechowywania, a co za tym idzie, będzie można ją sprawniej przechowywać i transportować.

Zarządzanie wilgocią

Ponieważ prasy do kiszonki przetwarzają mokre plony, wybór modelu z doskonałymi funkcjami zarządzania wilgocią jest kluczowy. Niektóre prasy są wyposażone w czujniki wilgotności, które pomagają zapewnić optymalne warunki fermentacji.

Trwałość

Wytrzymała prasa do kiszonki będzie działać dłużej i niezawodnie w trudnych warunkach polowych. Wybierz model z wytrzymałymi podzespołami i reputacją niezawodnej maszyny.

Prasy paszowe odgrywają kluczową rolę w zachowaniu wartości odżywczych roślin pastewnych, umożliwiając rolnikom karmienie zwierząt przez cały rok. Wykorzystując te maszyny do wydajnego zbioru, prasowania i owijania kiszonki, rolnicy mogą zmniejszyć ilość odpadów, zaoszczędzić na pracy i poprawić ogólną jakość paszy. Niezależnie od tego, czy prowadzisz małe gospodarstwo, czy dużą działalność komercyjną, wybór odpowiedniej prasy do kiszonki jest kluczowy dla zapewnienia obfitości, świeżości i wysokiej jakości paszy przez cały rok.

Rozumiejąc, jak działają prasy do kiszonki, jakie mają znaczenie i na jakie kluczowe cechy zwrócić uwagę, możesz podjąć bardziej świadomą decyzję o zakupie prasy do kiszonki dla swojego gospodarstwa. Dzięki odpowiedniemu sprzętowi zmaksymalizujesz produkcję paszy, zaoszczędzisz koszty oraz zadbasz o zdrowie i wydajność swojego bydła.

Prasy paszowe są niezbędne do zachowania wysokiej jakości paszy przez cały rok, co ma kluczowe znaczenie dla zdrowia i wydajności zwierząt gospodarskich. Inwestując w odpowiednią prasę do kiszonki, możesz nie tylko usprawnić działalność rolniczą, ale także zmaksymalizować wartość odżywczą zbieranej paszy.

Jeśli chcesz dowiedzieć się więcej o prasach do kiszonki lub potrzebujesz wskazówek dotyczących wyboru odpowiedniego modelu dla swojego gospodarstwa, odwiedź naszą stronę Skontaktuj się z nami stronę lub zapoznaj się z naszą szeroką ofertą Produkty do pras do kiszonki Aby znaleźć idealne rozwiązanie dla Twoich potrzeb. Niezależnie od tego, czy jesteś rolnikiem na małą skalę, czy prowadzisz dużą działalność komercyjną, jesteśmy tutaj, aby pomóc Ci podjąć najlepszą decyzję dla przyszłości Twojego gospodarstwa. Jeśli chcesz dowiedzieć się więcej o innych powiązanych i uzupełniających produktach, odwiedź naszą stronę. silage-baler.com